Whether you are building a new vessel or updating an existing one, adding new marine gauges can make a significant difference in the general finish of the dashboard. They can contribute both style and sophistication while also providing all of the functionality you require. However, it’s highly important to understand the types of marine gauges that exist on the market as well as the differences between them. Let’s dive deeper into that topic in our article.

What are Marine Gauges

Marine gauges are essential components of any ship or watercraft. This equipment is necessary for tracking data such as speed, oil pressure, oil level, battery condition, water temperature, and many other variables. These gauges facilitate the running of waterborne boats by transmitting this information to an easy-to-read screen or dial enabling you to have everything you need at your fingertips to ensure a safe and smooth sail.

Types of Marine Gauges

There are several gauges accessible for use on a marine vessel, including:

- Sounders for depth;

- Ammeter gauges;

- Rudder angle indicators;

- Fuel level indicators;

- Hourmeter displays;

- Oil pressure measuring gauges;

- Gauges for speedometers;

- Vacuum and turbo indicators;

- Tachometer gauges that can be set to operate with either diesel or gasoline engines;

- Trim level indicators;

- Gauges for synchronisation;

- Voltmeter indicators;

- Temperature sensors for water;

- Waste water level indicators.

The majority of boats, however, require a number of these gauges, which can result in a cluttered dashboard. This can make it challenging to read the data properly.

To avoid that, consider a multi-functional or digital gauge panel that incorporates multiple gauges on a single display unit. Regardless of whether you want a more traditional feel on the boat or want to go high-tech digital, there are a variety of gauges to put into the boat panel.

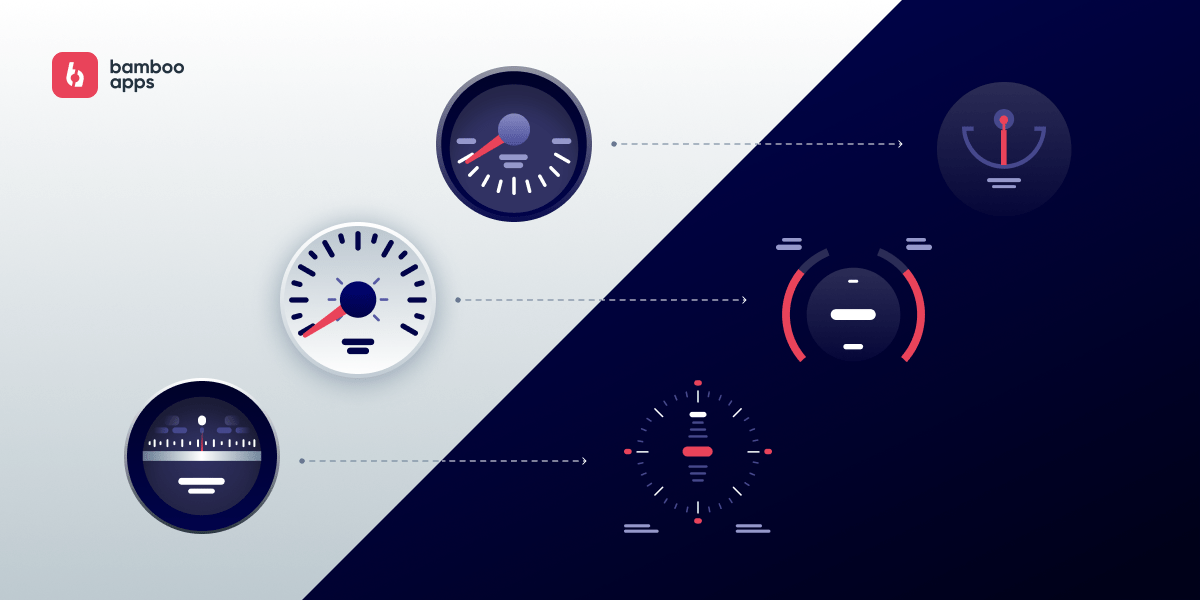

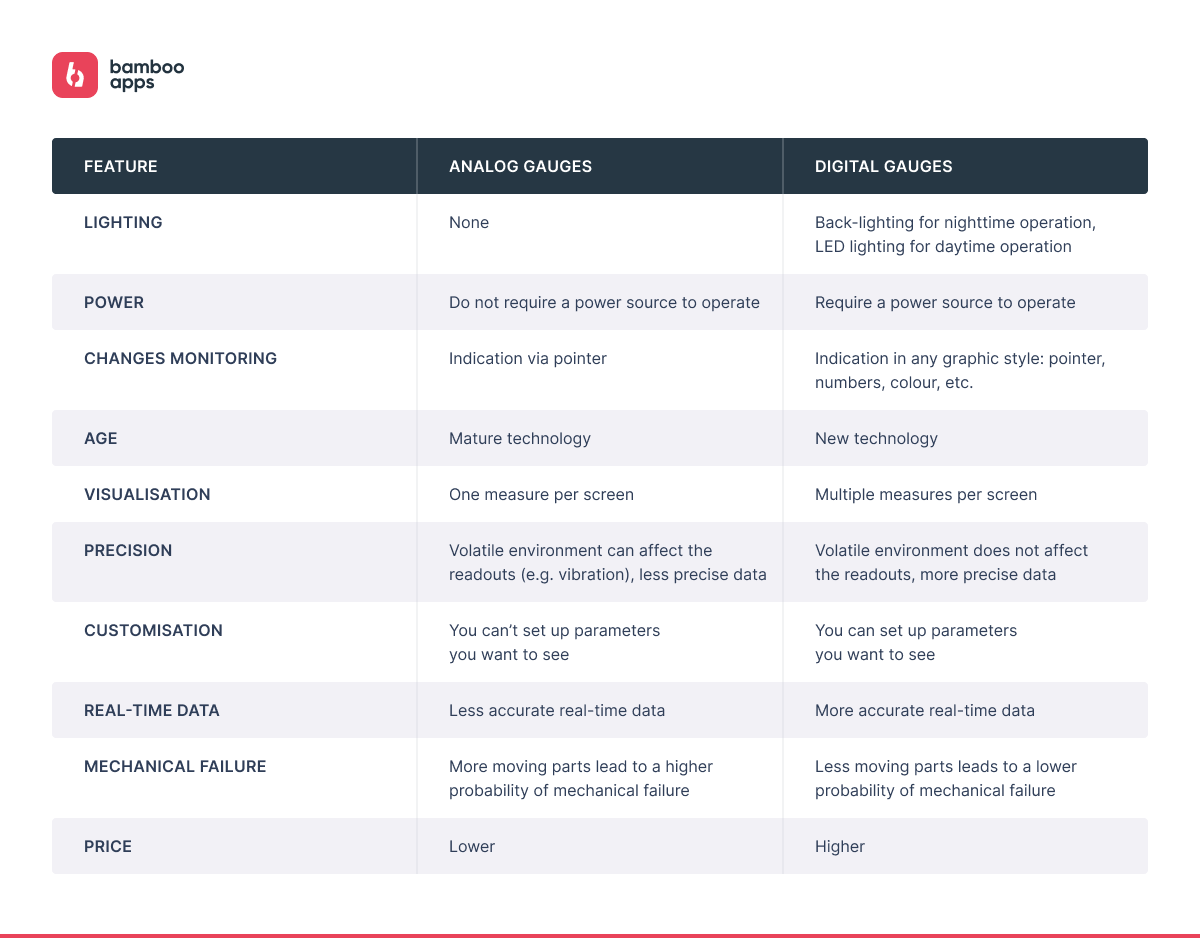

The first decision you must make is whether to use an analogue or a digital gauge. Both have a usage in the modern sailing and boating environment because they offer a variety of advantages.

Analog Marine Gauges

Analog gauges are traditional gauges with moving parts that can monitor a broad range of data. There are several advantages to using these over more contemporary digital gauges.

- Power. Because analogue gauges do not require a power source to operate, they can continue to function in the event of a power outage.

- Change is easy to spot. Because the changes being monitored are presented on a dial, it is simple to spot a change as the pointer moves and draws attention to itself.

- Mature technology. Analog dials have been in use for some time and are well embedded in the industry, which means they are simple to operate and, more importantly, simple to fix because many technicians are acquainted with them. Furthermore, if a digital gauge’s display fails, all data flowing through it is made inaccessible, whereas each analogue gauge is independent of the others.

- Easy to read. The data on an analogue gauge may be simpler to read than the displays on a digital gauge. What you see is frequently what you get, and they are simple to comprehend.

Although analogue technology is old, it is still evolving, with some models including LCD screens that display more information than just the primary needle pointer.

Digital Marine Gauges

Many modern vessels prefer digital gauges for their simplicity of use and installation, as well as to match the sleek, streamlined appearance of a modern vessel. Digital marine gauges are a developing technology that comes in two varieties:

- CANbus Gauges, in which the digital data is connected to a CANbus network.

- Touch screen, plug-and-play marine engine monitors with pre-installed dial styles based on traditional analogue style gauges that can be viewed on a single display or separately.

Regardless of which method you choose, digital has several advantages over analogue, including:

- Lighting. Digital boat gauges can be viewed more easily in both daylight and at night. LED lighting reduces glare from the sun, and backlighting improves visibility in low-light conditions.

- Real-time data. Unlike analogue systems, digital gauges for boats can show more accurate real-time data on a single display screen. This makes analysing data like engine output, fluid levels, and speed much more effective and straightforward.

- Precision. Boat digital gauges are much more exact with data than analogue gauges, so they can be used in more volatile environments, such as those with high levels of vibration, without affecting the readouts.

- Customisable. Many digital sensors can be customised to display only the necessary information in an easy-to-read display.

- Less to go wrong. Because digital marine gauges have fewer moving components than analogue gauges, they are more reliable and have the potential to last longer.

- Higher quality. Although more costly, many marine digital gauges are developed with higher quality materials such as aluminium or stainless steel, as well as scratch- and crack-resistant glass, which means they may last longer due to general wear and tear.

- Compact. While analogue gauges may require more than one gauge to read certain features, digital marine gauges require less hardware because all data is presented on a single screen, making the dashboard less cluttered.

When selecting gauges, ensure they can endure a marine environment and exposure to the elements. Good quality gauges should have IP67 protection ratings, which prevent them from dust and water immersion for up to 30 minutes at the depth of one metre. Other protections to look for include scratch-resistant wraps and anti-fogging gauge bodies, which guarantee the equipment’s longevity.

Custom Marine Gauges

Off-the-shelf maritime gauges may not always meet your exact specifications, which is why you have the option of making a custom one. This means you can outline your particular requirements and have a gauge produced that is perfectly tailored to the vessel.

The beauty of custom gauges is that ‘hybrid’ gauges can be made for displays with both analogue and digital inputs. This allows the gauge to receive data from the CANbus and the older analogue instruments and senders.

Additionally, gauges can be customised to match the general style and aesthetic of the vessel, which means it will look great with embossed metal, brushed aluminium, plastic bezels, back-lit or edge-lit displays, and so on.

Custom gauges can be developed for specialised hardware devices using proprietary platforms, or for a wide range of displays using open-source OS such as Android.

You can choose the type of development software depending on the requirements for the interface and the customisation level of the display model. But keep in mind that open-source solutions will give you maximum flexibility.

Custom Marine Gauge Project Example

Bamboo Apps has developed a custom display UI for a range of electric vessels using the proprietary iQAN platform created by the display manufacturer Parker Hannifi. The team created an intuitive, modern, and practical graphical user interface (GUI) that adhered to all of the client’s brand standards. As a result, the solution perfectly matched the design and style of the client’s vessels.

It allowed users to monitor and control said vessels by using data channels linked to various parts of each boat via the CAN bus. Boat operators could view detailed information about the vessel on the home and system screens, manage charging, view settings, record data, get notifications, and check for updates and maintenance schedules.

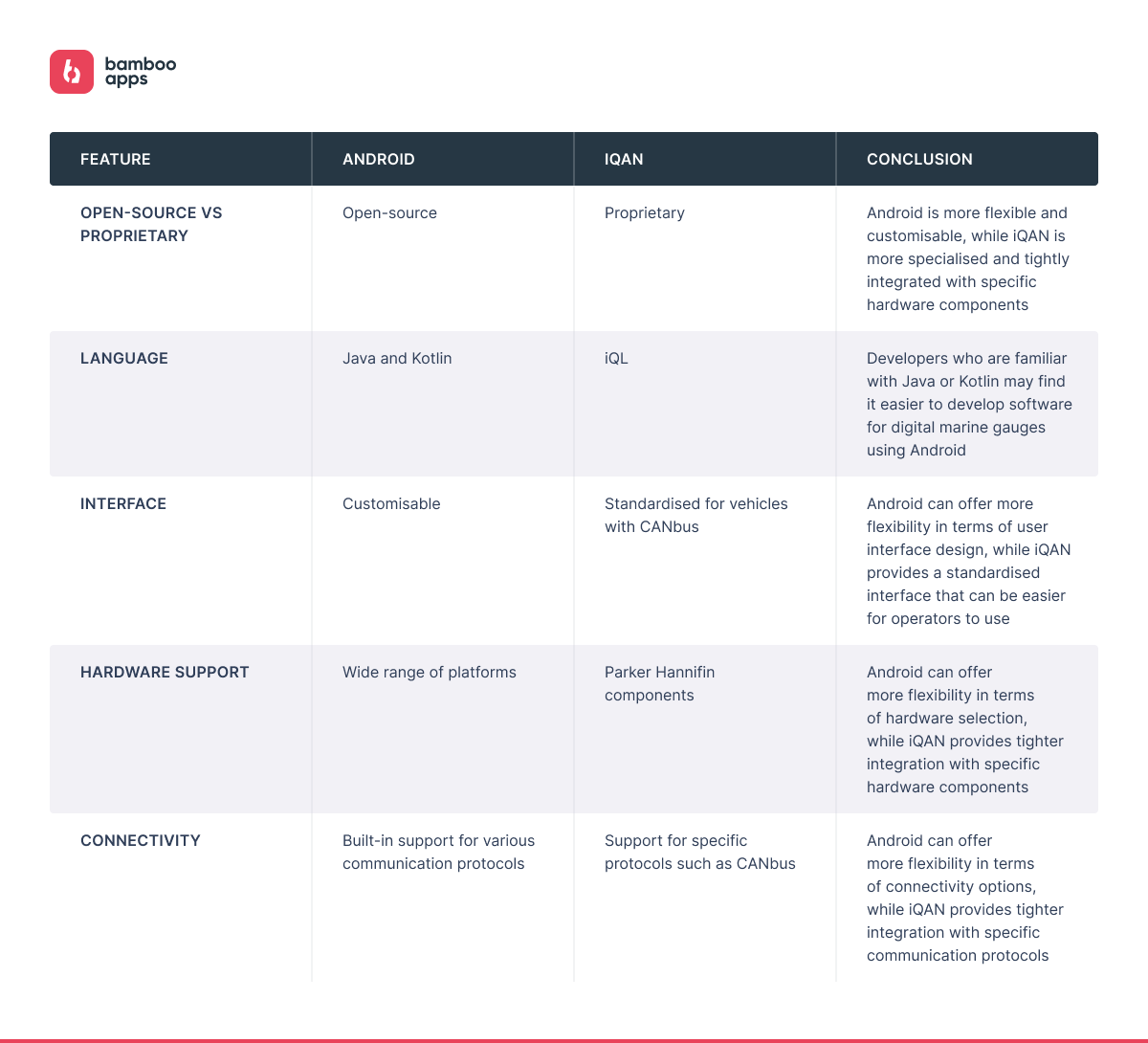

For a better understanding of the iQAN platform, let’s compare it to the popular open-source OS Android. Android and iQAN are two different platforms that can be used for digital marine gauge development. Both systems have similarities and differences, so let’s visualise them with a comparison table.

Overall, the choice between Android and iQAN for digital marine gauge development will depend on the hardware platform. It means if you have Parker, then you have a choice between IQAN and Android, otherwise IQAN is simply not applicable.

Analog vs Digital Marine Gauges

Now let’s compare analogue and digital marine gauges based on their features.

Digital Marine Gauges HMIs

If you are a marine vessel manufacturer, there is no doubt that the question of which gauges to implement into the boat arises every time you construct one. In many cases, the only way to display all the metrics you need is to combine different gauges into one. And sometimes two sensors with multiple measures can have two or more similar gauges, too.

The most elegant way to solve this riddle is to develop a custom gauge. Usually, gauge development companies do not have the resources to create an HMI for such a sensor. In that case, it is worth asking for assistance from an HMI development company. While choosing a development partner, it’s highly important to request cases of successful HMI development for vessels.

There are some best practices that are specific to developing digital marine gauges HMIs for vessels. Here are a few:

- Ergonomic Design. Consider the physical environment in which the interface will be used. The interface should be designed to be ergonomic and easy to use in different conditions such as rough seas, low light, or high humidity.

- Intuitive Navigation. The navigation of the interface should be simple and intuitive, even in challenging conditions. Operators should be able to quickly access the information they need without having to search through multiple screens or menus.

- Standardised Icons and Symbols. Use standardised icons and symbols that are widely recognized by operators in the marine industry. This will reduce confusion and increase efficiency, as operators will not need to learn what the new design elements mean.

- Information Hierarchy. The interface should prioritise the most critical information and display it prominently. Use colour, size, and positioning to indicate the importance of different data.

- Redundancy. Provide extra displays for critical information such as navigation, propulsion, and safety systems. This ensures that operators have access to important information even if one display fails.

- Cybersecurity. Ensure that the HMI is designed with cybersecurity in mind. Use best practices for securing the interface and data transmission. This includes using encryption, authentication, and access control.

- Reliability. Reliability is critical for any marine gauge HMI. Vessels operate in harsh environments, and the HMIs must be able to withstand the rigours of sea travel. Developers should use protected hardware and software that can withstand shock, vibration, and extreme temperatures. In addition, redundant systems can be used to ensure that critical functions are always available, even if one system fails.

- Low Latency. Real-time data is critical for vessel operators to make informed decisions, and any delays in data transmission can have significant consequences. Developers should minimise latency by using high-speed communication protocols and optimising the software and hardware to reduce processing times.

By following these best practices, developers can create digital marine gauges HMIs that are effective and efficient in helping operators monitor and control the systems of the vessel.

Conclusion

There are many different kinds of vessel gauges on the market, but which one is best for you? The best gauge for your boat depends on the type of vessel. More traditional boaters prefer using analogue gauges, while younger generations prefer digital ones. But perhaps the perfect option for your vessel is a custom solution with a specially designed UI for digital marine gauges.

In this article, we’ve gathered the most important information about different types of marine gauges. If you are considering a custom UI for your vessel’s digital gauge, consider contacting Bamboo Apps. Our experienced team of professionals would be happy to help you on your journey!